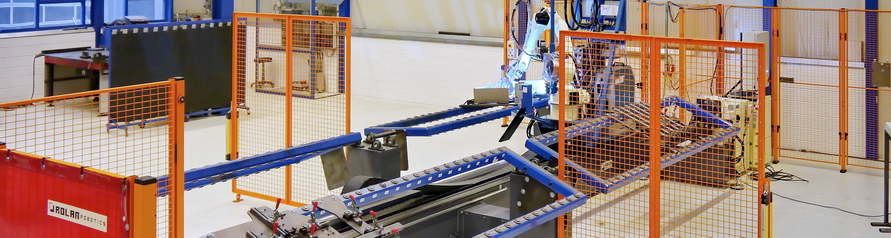

new welding robot now in operation

03-12-2013

This month we started using our new welding robot - a fantastic moment for our organisation, but above all excellent news for our customers. Now, when it comes to welding work, you no longer have to choose between efficiency and quality - the new robot enables us to offer you the best of both worlds.

When we went in search of the ideal welding robot it became apparent that no existing model could satisfy all our requirements. We therefore combined our own knowledge of engineering and machine building with the expertise of Rolan Robotics and developed one together. The result is an ultramodern welding robot that is unique in the Netherlands.

key specifications

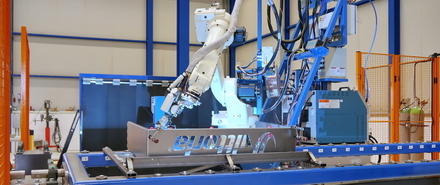

- Number of axes: 6 axes and 5 external axes

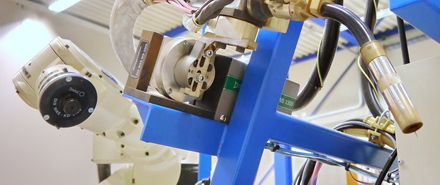

- Switching time for welding guns: several seconds

- H-reach: 2,006 millimetres

- Length of workpieces: up to 8 metres

high degree of dimensional stability and repeat accuracy

What is special about our new robot is that the external axes are not coupled to the welding line as separate modules - the robot is built as a single integrated machine. The strength this gives the machine means we can guarantee a very high degree of dimensional stability - even at the high speeds that we are able to achieve. Furthermore, the repeat accuracy is much greater than can be achieved with traditional welding robots, making it particularly suitable for repeat orders.

mig/mag and tig welding

A second advantage of the new robot is that it can perform both MIG/MAG and TIG welding, without the need for the machine to be reconfigured manually. Thanks to a unique, automated system that allows welding guns to be switched rapidly, we can weld different parts made from different materials (steel, aluminium and stainless steel) using various welding techniques in a single pass. This enables us to make huge efficiency gains, particularly in the case of large production series consisting of various types of components.

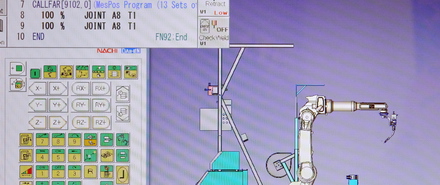

offline programming

On the subject of efficiency, we can also program our new robot offline. As we have the knowledge in house to make accurate drawings and welding fixtures, this saves us a huge amount of time, especially when it comes to smaller series. The benefits include: less downtime, more effective production time, higher efficiency, and lower costs.

want to outsource your welding work?

Do you want to outsource your welding work? Besides robotic welding we can also take care of TIG welding, MIG/MAG welding, spot welding and stud welding. Why not contact us?

« to overview